- A University of Michigan innovation enables electric vehicles (EVs) to maintain robust performance and ultra-fast charging in sub-freezing temperatures.

- The breakthrough technology involves a 20-nanometer-thick lithium borate-carbonate coating, which prevents lithium plating within EV batteries.

- This protective layer allows EV batteries to charge up to 500% faster, taking under 10 minutes even at 14°F (-10°C).

- The new technology integrates seamlessly into existing manufacturing processes, requiring no drastic production line changes.

- This advancement addresses cold-weather range anxiety, promising an EV experience similar to traditional vehicles, regardless of climate.

- The future landscape for EVs looks promising, with enhanced charging capabilities and increasing accessibility across urban and rural areas.

When winter’s icy breath descends, the world seems to slow down—traffic snarls, fingers freeze, and cars, especially electric ones, struggle. The frosty bite of winter has long been a nemesis to electric vehicle (EV) owners, who find their battery ranges shortened and charging times stretched painfully long. However, a breakthrough from the University of Michigan might just rewrite the script for cold-weather performance.

Amidst the swirling snowflakes, engineers have discovered a way to shield EV batteries from winter’s chill, allowing for ultra-fast charging and robust performance despite sub-freezing temperatures. Think of it as wrapping your battery in a high-tech parka.

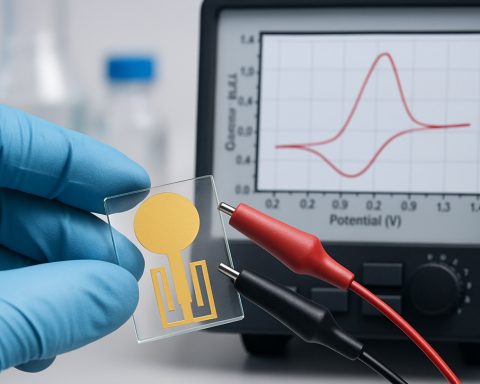

At the heart of this innovation lies a wafer-thin coat—just 20 nanometers thick—of lithium borate-carbonate. This glassy layer acts as a guard against lithium plating, a malicious crust that forms when lithium ions struggle to find their home within the battery’s anode. With this barrier in place, batteries can sidestep several issues that plague traditional ones: reduced lifespan, slower charging, and safety risks.

By marrying this innovative coating with a cutting-edge electrode design, the researchers have achieved something akin to alchemy for EV batteries. Faster than filling up at the pump, the new setup allows batteries to charge approximately 500% faster than current capabilities—taking under 10 minutes, even when the mercury dips to a brisk 14°F (-10°C).

Despite this technological leap, existing battery manufacturers won’t need to turn their operations upside down. The transition is seamless, promising a practical application without drastic overhauls in the production line. This forward-thinking solves a pressing issue that has left many EV drivers shivering with range anxiety during the colder months.

The University of Michigan’s breakthrough hints at a future where EV drivers can enjoy the convenience of traditional vehicles without the compromises that come with cold climates. As charging stations continue to populate cityscapes and rural areas alike, and with technology like this advancing, the road ahead for EVs looks less like a winter wonderland and more like a smooth ride into a sustainable future.

No longer bound by the icy chains of winter, electric vehicles may soon dart forward with the same speed and reliability as their fossil-fueled counterparts, leaving behind the anxieties of yesteryear for good.

Revolutionary Solution for EVs: Beat the Cold with New Battery Technology

Exciting Advancements in EV Battery Technology

As electric vehicles (EVs) gain popularity, their challenges in cold climates have been a significant drawback for many consumers. However, groundbreaking research from the University of Michigan has unveiled a promising solution to enhance electric vehicle performance during winter by introducing a thin layer of lithium borate-carbonate on batteries. This technological advancement aims to improve both charging speed and battery lifespan under sub-freezing conditions.

How the Innovation Works

The innovation revolves around a 20-nanometer thin glassy coating applied to battery components. This layer acts as a protective barrier between lithium ions and the battery’s anode, significantly reducing issues such as lithium plating, which can cause:

– Reduced Battery Lifespan: Traditional batteries often see decreased performance in cold weather due to ion movement challenges, but this coating helps maintain longevity.

– Slower Charging Times: By preventing the formation of lithium plating, the coating allows batteries to charge up to five times faster, even at low temperatures as cold as -10°C (14°F).

– Safety Risks: The coating minimizes the risk of short circuits and other safety hazards associated with cold-induced battery stress.

Real-World Use Cases and Industry Trends

This breakthrough positions EVs as viable year-round modes of transportation, even in regions with harsh winters. As governments increase investments in charging infrastructure, EV adoption is expected to grow significantly. Forecasts indicate a steady increase in electric vehicle production, potentially reaching up to 30% of the global automotive market by 2030.

Reviews & Comparisons

– Current Limitations: While traditional lithium-ion batteries lose performance and efficiency in the cold, this new technology offers a comparable performance to internal combustion vehicles, eliminating “range anxiety.”

– Competitive Edge: EV models that adopt this technology first could gain a substantial market advantage in northern climates.

Potential Challenges

Despite its promises, the technology needs to be tested thoroughly in real-world conditions over time. Further analysis is necessary to determine if this innovation will hold up consistently in user environments and various battery chemistries beyond initial lab results.

Security & Sustainability

The approach is designed to integrate smoothly into existing manufacturing processes, ensuring a low barrier to entry for battery producers. Moreover, it aligns with sustainable development goals by reducing the environmental footprint of EVs, especially in terms of reducing battery waste and extending usable life.

Quick Tips for EV Owners

– Prepare for Cold Weather: If you own an EV, pre-condition your vehicle by warming it up while it’s still connected to the charger before driving in cold weather.

– Maximize Battery Health: Familiarize yourself with your EV’s charging guidelines as new technology becomes mainstream to get the most out of your vehicle’s capabilities.

Conclusion

The University of Michigan’s development is a major leap forward in making electric vehicles more practical and reliable in all climates. This innovation not only addresses pressing challenges but opens the door for more widespread EV adoption, especially in colder regions. With infrastructure and technology progressing hand in hand, the future of transportation looks electrifying and eco-friendly.

For more updates on evolving technology and breakthroughs, visit the University of Michigan website.