- The transition to electric vehicles (EVs) is heavily reliant on critical minerals, with China dominating the graphite supply essential for lithium-ion batteries.

- China’s near-monopoly on battery-grade graphite poses challenges for Western automotive industries due to mineral shortages expected through 2030.

- Biographite emerges as a sustainable alternative, derived from renewable forestry by-products, reducing supply chain dependency and environmental impact.

- Automakers like Ford and GM face economic pressures, making biographite an appealing, cost-effective solution amid global market uncertainties.

- Biographite offers a path to locally sourced, carbon-zero vehicles, emphasizing sustainability and innovation in EV production.

- The shift to biographite highlights the need for strategic partnerships and investment in visionary materials for a resilient future in electric mobility.

A crucial juncture in the electric vehicle (EV) saga unfolds. As the world accelerates its embrace of electric mobility—with sales skyrocketing to new heights—an unseen battle over the minerals fueling this shift is heating up. China stands as the unchallenged titan, commanding a broad sweep of resources essential for this transition. This dominance is particularly stark in the graphite sector, a critical component of lithium-ion batteries, where China holds near-monopolistic power.

Imagine a world where nearly every electric vehicle relies on graphite shepherded from this one powerhouse nation. China produces 77% of natural graphite and over 95% of synthetic graphite, but its grip tightens further with almost absolute control over the battery-grade variant. This dependency sets a precarious stage for Western automotive industries, left scrambling for alternatives amidst forecasts of persistent mineral shortages through 2030.

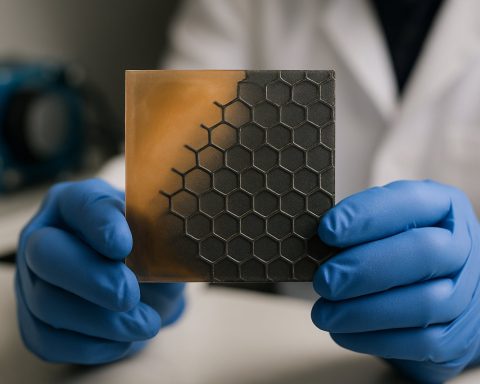

Yet, as these challenges mount, innovation emerges as a beacon of hope. A new player strides onto this fraught stage: biographite—crafted not from deep earth mines but from renewable forestry by-products. This leap in technology draws a vision where supply chains are not only local and sustainable but also significantly less carbon-intensive. By pivoting to this domestic resource, we unveil a path that not only undercuts the need for sprawling supply lines but also lightens the environmental footprint of battery production.

The implications entwine economics with ecology. Automakers, like Ford and GM, grappling with the high costs and risks of complex global supply chains may find solace in biographite’s promise. As they struggle within tight financial forecasts, including Ford’s $5 billion projected EV division loss by 2025, the allure of a cheaper, locally-sourced alternative becomes undeniable. Moreover, the pressure from soaring tariffs and potential trade disruptions further underscores the urgency to innovate.

Through biographite, a once overlooked forestry by-product, the narrative of EV production could pivot away from international dependency. As automakers integrate this new material, it offers not only a cost-efficient solution but also the promise of a carbon-zero vehicle—anchoring sustainability as a core production value.

This isn’t just about manufacturers saving money; it’s about redefining the future of energy. The lesson here is clear: to weather the uncertain tides of global trade and environmental urgency, investing in visionary materials like biographite is paramount. It mandates a strategic pivot, one where nations and industries collaboratively forge a resilient, environmentally harmonious path forward.

In this electrifying new era, could the silent giants of our forests steer us toward a sustainable automotive future? They just might.

Could Biographite Revolutionize the Electric Vehicle Market?

Understanding the Current Predicament

The electric vehicle (EV) market is at a transformative crossroads, with China wielding substantial control over critical minerals like graphite, crucial for lithium-ion battery production. As the world pivots towards greener technology, the reliance on China for these materials presents significant strategic challenges, particularly for Western automakers.

The Challenge of Graphite Dependency

– Market Dominance: China accounts for 77% of natural graphite production and over 95% of synthetic graphite. More crucially, China’s control over battery-grade graphite is nearly absolute.

– Supply Chain Vulnerabilities: This dependency poses risks of supply interruptions and price volatility, which could severely impact the cost and availability of electric vehicles in the global market.

Enter Biographite: A Sustainable Alternative

Biographite emerges as a promising alternative, offering a solution to the challenges of current graphite sourcing.

Advantages of Biographite

– Renewable Resource: Derived from renewable forestry by-products, biographite reduces reliance on traditional mining practices, which are often environmentally damaging and resource-intensive.

– Sustainability: Using locally sourced biographite can significantly lower the carbon footprint associated with battery production, aligning with global sustainability goals.

– Economic Impact: Automakers like Ford and GM could reduce their costs by utilizing biographite, alleviating financial strains from projected losses, such as Ford’s expected $5 billion EV division loss by 2025.

– Reduced Trade Risks: By lessening dependency on international supply chains, automakers can evade potential trade disruptions and high tariffs.

Real-World Use Cases & Industry Trends

– Adoption by Automakers: Companies can integrate biographite into their supply chains to gain cost efficiency and ecological benefits, potentially setting new industry standards.

– Emerging Markets: There is growing interest and investment in biographite production facilities, particularly in regions keen to reduce reliance on imported minerals.

Challenges and Controversies

– Initial Costs: Developing biographite production capabilities requires significant initial investment in technology and infrastructure.

– Technical Viability: While promising, biographite technology must demonstrate that it can consistently meet the performance standards required for high-capacity batteries.

Actionable Recommendations

1. Investment in Research: Governments and companies should encourage research into biographite to enhance its efficiency and feasibility.

2. Policy Support: Legislations favoring sustainable materials in manufacturing could accelerate biographite adoption.

3. Public Awareness: Increasing consumer awareness about the benefits of biographite could drive demand for products using sustainable materials.

Conclusion

Biographite stands out as a beacon of hope in the realm of electric vehicle production, promising reduced environmental impact and economic efficiency. By embracing this innovative material, the automotive industry can lead a shift towards sustainability while safeguarding against geopolitical risks associated with mineral imports.

Explore more about the future of EVs on [Tesla](https://www.tesla.com) and other leading automakers as they navigate this exciting frontier.