Table of Contents

- Executive Summary: Market Snapshot & Key Takeaways for 2025–2030

- Technology Landscape: Leading Zeaxanthin Extraction Methods from Microalgae

- Key Players & Company Innovations (2025 Update)

- Regulatory Trends: Global Guidelines and Compliance for Microalgae-Derived Zeaxanthin

- Market Size & Forecast: Growth Projections Through 2030

- Investment & Funding Trends in Zeaxanthin Extraction Startups

- Downstream Applications: Nutraceuticals, Food, and Pharma Opportunities

- Sustainability & Environmental Impact of Extraction Technologies

- Emerging Markets: Geographic Hotspots & Regional Demand Analysis

- Future Outlook: Disruptive Technologies and Strategic Roadmap for Industry Stakeholders

- Sources & References

Executive Summary: Market Snapshot & Key Takeaways for 2025–2030

The global landscape for zeaxanthin extraction from microalgae is entering a pivotal phase as we move into 2025, driven by escalating demand for natural carotenoids in the nutraceutical, food, and cosmetic industries. Zeaxanthin, recognized for its eye health benefits and antioxidant properties, is increasingly sourced from microalgae due to its high purity and sustainability credentials compared to synthetic alternatives. This section provides a concise overview of the market status and key drivers shaping extraction technologies in the near term.

- Technology Advances: The microalgae sector is witnessing rapid innovation in extraction methods. Supercritical CO2 extraction, ultrasound-assisted extraction, and green solvent systems are gaining traction as energy-efficient and scalable alternatives to traditional solvent extraction. Companies such as Algatech are at the forefront, leveraging proprietary green extraction processes to increase yield and purity while adhering to clean-label requirements.

- Commercialization & Scale: Recent investments in industrial-scale photobioreactors and harvesting systems, notably by DSM and Parry Nutraceuticals, underscore the sector’s readiness for mass production. These advancements enable consistent biomass supply and facilitate downstream processing, critical for meeting expanding global demand.

- Regulatory Trends: Regulatory acceptance of microalgal zeaxanthin as a food ingredient and dietary supplement is expanding in key markets, notably the EU and US, reinforcing the outlook for new product launches. Companies are investing in process validation and traceability, anticipating stricter quality and safety standards in the coming years.

- Market Drivers: The transition from synthetic to natural ingredients remains a powerful driver, with consumer preference for sustainable and plant-based sources accelerating adoption. The functional foods and supplements segment, in particular, is fueling demand for high-purity zeaxanthin extracts.

- Outlook 2025–2030: The next five years will likely see further optimization of extraction processes, with a focus on cost reduction, waste minimization, and enhanced bioavailability of zeaxanthin. Partnerships between technology providers and ingredient manufacturers are expected to intensify, while ongoing R&D will address challenges related to scalability and regulatory compliance.

In summary, zeaxanthin microalgae extraction technologies are poised for robust growth, supported by technological advancements, regulatory progress, and strong market demand. Industry leaders such as Algatech, DSM, and Parry Nutraceuticals are well-positioned to drive innovation and shape the competitive landscape through 2030.

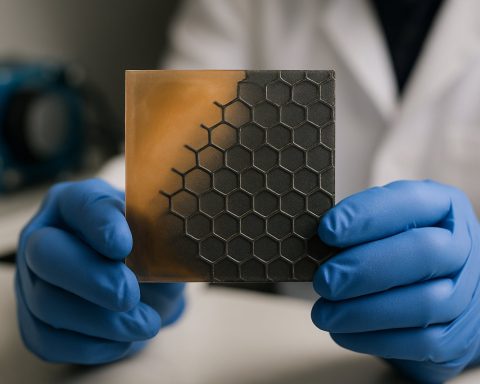

Technology Landscape: Leading Zeaxanthin Extraction Methods from Microalgae

The extraction of zeaxanthin from microalgae has seen significant advancements in recent years, with a growing emphasis on sustainable, efficient, and scalable technologies. As of 2025, companies and research institutes are increasingly focusing on optimizing extraction yields while minimizing environmental impact and production costs. The following summarizes the current technology landscape and outlook for zeaxanthin microalgae extraction.

- Supercritical CO2 Extraction: This method remains a leading technology for extracting zeaxanthin due to its efficiency and avoidance of toxic solvents. Companies such as Algatech (a subsidiary of Solabia Group) utilize supercritical CO2 for their microalgae-derived carotenoids, including zeaxanthin. The process offers high selectivity and purity, and recent process improvements are enabling better scalability and lower energy consumption.

- Solvent Extraction and Green Solvents: Traditional solvent extraction using ethanol or acetone is still in use, especially at smaller scales. However, sustainability concerns are driving adoption of “green” solvents such as ethyl lactate and ionic liquids. Fuqing King Dnarmsa Spirulina Co., Ltd. is among the companies that have shifted focus toward safer, food-grade solvents in their production lines in 2024–2025, aligning with global regulatory trends.

- Enzyme-Assisted Extraction: Enzymatic pretreatment, often combined with mild physical disruption, is gaining traction as a means to enhance zeaxanthin yield while preserving bioactivity. Companies like DSM-Firmenich are investing in enzyme-based protocols that improve cell wall breakdown and increase extraction efficiency, with pilot-scale deployments expected to expand in the next two years.

- Ultrasound-Assisted and Microwave-Assisted Extraction: These emerging technologies are being adopted for their ability to intensify mass transfer and reduce extraction time. Parry Nutraceuticals has reported ongoing R&D in combining ultrasound and microwave techniques with green solvents to further improve zeaxanthin recovery from microalgae biomass.

- Continuous and Integrated Processing: The trend toward continuous, inline extraction and purification is notable, particularly among producers targeting high-volume markets. Ebbecke Verfahrenstechnik is working with commercial partners to integrate downstream processing steps, such as membrane filtration and chromatographic purification, for high-purity zeaxanthin concentrates.

Looking forward, the sector is expected to see further innovation in hybrid extraction methods—combining physical, enzymatic, and solvent-based techniques—to maximize yield and purity while reducing carbon footprint. Regulatory pressures, particularly in the EU and North America, are accelerating the adoption of food-safe and environmentally benign extraction technologies. Overall, the next few years will likely witness a transition from batch to continuous extraction processes, with increased automation and digitalization contributing to greater efficiency and traceability in zeaxanthin production from microalgae.

Key Players & Company Innovations (2025 Update)

The global drive for natural antioxidants and colorants in nutraceutical, food, and cosmetic segments is accelerating advancements in zeaxanthin extraction from microalgae, with 2025 marking notable technological and commercial milestones. Key players are optimizing both upstream cultivation and downstream extraction to enhance zeaxanthin yield, purity, and sustainability.

Algatech, a subsidiary of Solabia Group, remains a leader with its proprietary closed tubular photobioreactor systems for Haematococcus pluvialis and Porphyridium microalgae, which facilitate controlled biomass growth and minimal contamination. In 2025, Algatech has further refined its supercritical CO2 extraction platform—an eco-friendly process that eliminates organic solvents and enhances zeaxanthin purity while maintaining bioactivity. The company’s investments in automation and real-time analytics have reduced processing times, supporting larger batch throughput and cost efficiency. Algatech’s microalgal zeaxanthin is now integrated into various eye health and functional food products globally (Solabia Group).

Meanwhile, Parry Nutraceuticals, part of the EID Parry (India) Limited group, has expanded its microalgae platform, leveraging decades of expertise in phototrophic cultivation. Parry’s patented extraction technologies incorporate gentle cell disruption (bead milling) combined with food-grade solvent extraction and advanced filtration, achieving high-purity zeaxanthin suitable for dietary supplements and fortified foods. In 2025, the company has initiated pilot trials using enzymatic pre-treatment, which further improves extraction efficiency and reduces energy input.

In Europe, BGG (Beijing Gingko Group) continues to scale up its integrated microalgae production in Spain, using closed-system fermentation and membrane-based extraction techniques. In 2025, BGG has reported successful deployment of membrane filtration and chromatographic purification, resulting in zeaxanthin concentrations exceeding 10% by weight. This aligns with increasing regulatory requirements for high-purity bioactives.

Outlook for the next few years focuses on sustainability and scalability. Companies are investigating green solvents (e.g., ethanol, water-based systems) and continuous flow extraction to further reduce carbon footprint and operational costs. Additionally, collaborative R&D initiatives are aiming to genetically optimize microalgae strains for higher zeaxanthin content and resistance to photo-oxidative stress, which could reshape the economics of large-scale production. As regulatory and market demand for natural zeaxanthin intensifies, technology-driven players are poised to capture a larger share of the value chain by offering cleaner, safer, and more cost-effective extracts.

Regulatory Trends: Global Guidelines and Compliance for Microalgae-Derived Zeaxanthin

In 2025, the regulatory landscape for microalgae-derived zeaxanthin extraction technologies is rapidly evolving, reflecting growing commercial interest and consumer demand for natural carotenoids in food, nutraceutical, and pharmaceutical applications. Regulatory bodies across major markets are updating guidelines to address both the safety and traceability of zeaxanthin sourced from microalgae, ensuring products meet quality standards and are free from contaminants.

In the United States, the Food and Drug Administration (FDA) continues to supervise the use of zeaxanthin as a dietary ingredient, focusing on compliance with Good Manufacturing Practices (GMP) for extraction processes. Companies like Kemin Industries, a major producer of microalgae-sourced carotenoids, align their extraction and purification procedures with FDA requirements, utilizing solvent-free and supercritical CO2 extraction technologies to ensure product purity and safety. FDA’s 2025 emphasis includes detailed documentation of extraction solvents and processing aids, as well as validated testing for residual contaminants.

The European Food Safety Authority (EFSA) and European Commission are reinforcing regulations for novel foods, including microalgae-derived zeaxanthin, under Regulation (EU) 2015/2283. Companies such as Fermentalg and AlgaeTech are actively working with EU authorities to demonstrate the traceability of their extraction processes and the absence of genetically modified organisms (GMOs) in their production lines. In 2025, EFSA is expected to finalize harmonized specifications for zeaxanthin extracted from various microalgae species, with a focus on process validation and batch-to-batch consistency.

In Asia-Pacific, China’s National Medical Products Administration (NMPA) and Japan’s Ministry of Health, Labour and Welfare (MHLW) are expanding oversight on functional ingredients sourced from microalgae. Chinese manufacturers like Fuqing King Dnarmsa Spirulina Co., Ltd. are increasingly adopting closed-system photobioreactor technologies to comply with stricter standards on heavy metals and microbial safety in algal extracts.

Globally, the adoption of ISO 22000 and FSSC 22000 food safety standards is becoming commonplace for large-scale zeaxanthin producers, enhancing international acceptance and marketability. The next few years will likely see further harmonization of extraction guidelines, particularly regarding permissible extraction solvents and toxin monitoring, to facilitate cross-border trade and regulatory approvals. Industry-wide, the focus is on transparent, auditable processes and advanced extraction technologies, setting the stage for broader adoption and innovation in microalgae-derived zeaxanthin production.

Market Size & Forecast: Growth Projections Through 2030

The market for zeaxanthin derived from microalgae is experiencing notable growth, driven by rising demand in nutraceuticals, eye health supplements, and food fortification. As of 2025, industry stakeholders are focused on advancing extraction technologies to improve yield, purity, and cost-efficiency, positioning microalgae as a sustainable, high-value source of zeaxanthin.

Recent years have seen leading microalgae producers scaling up their extraction operations. Euglena Co., Ltd., for example, has expanded its microalgae cultivation and downstream processing capabilities in Japan, emphasizing the potential for commercial production of carotenoids like zeaxanthin. Similarly, Algatech Ltd. in Israel continues to invest in proprietary supercritical CO2 extraction, which enhances the recovery of zeaxanthin without the use of organic solvents, ensuring a cleaner, food-grade product.

The global market size for zeaxanthin microalgae extraction technologies, including equipment, consumables, and integrated solutions, is projected to exceed USD 180 million by 2030, with a compound annual growth rate (CAGR) surpassing 8% from 2025 onward. This growth is supported by ongoing R&D efforts, such as those by DSM-Firmenich, which is advancing scalable, energy-efficient extraction platforms tailored for both Chlorella and Dunaliella species.

In 2025, technology providers are prioritizing eco-friendly extraction methods. Ultrasonic-assisted and enzymatic extraction are gaining traction, as evidenced by developments from Phytoneering Extract Solutions, which has piloted continuous-flow systems to increase zeaxanthin yield while minimizing input of hazardous reagents. Additionally, membrane-based separation technologies are being refined to allow selective enrichment of zeaxanthin fractions, a focus area for Cyanotech Corporation in Hawaii.

Looking to the next few years, industry analysts anticipate further consolidation of extraction technology suppliers and deeper collaboration between microalgae cultivators and end-use application developers. Regulatory approvals for microalgal zeaxanthin in major markets such as the European Union and the United States are likely to accelerate, opening new revenue avenues for producers who can demonstrate sustainable, high-purity extraction processes.

In summary, the outlook for zeaxanthin microalgae extraction technologies through 2030 is robust, marked by technological innovation, expanding commercial capacity, and growing acceptance in health-focused sectors. Companies investing in advanced, eco-friendly extraction solutions are poised to capture significant market share as global demand for natural, microalgae-derived zeaxanthin continues its upward trajectory.

Investment & Funding Trends in Zeaxanthin Extraction Startups

The landscape for investment and funding in zeaxanthin microalgae extraction startups is rapidly evolving as global demand surges for natural carotenoids in nutraceuticals, foods, and cosmetics. In 2025, this momentum is driven by advances in extraction technologies and the push for sustainable, plant-based bioactives. Startups are attracting both venture capital and corporate investors eager to capitalize on scalable, eco-friendly extraction processes from microalgal sources such as Dunaliella salina, Chlorella, and Haematococcus pluvialis.

Several notable investment events have occurred in the past year, reflecting the sector’s vibrancy. For instance, Algatech, an established player known for microalgae cultivation and extraction in Israel, announced in early 2025 a new partnership with a European venture fund to accelerate commercial-scale zeaxanthin extraction using proprietary supercritical CO2 methods. This follows their previous successes in astaxanthin and fucoxanthin, underscoring investor confidence in cross-carotenoid technology platforms.

In Asia, Fuqing King Dnarmsa Spirulina—a major spirulina and microalgae ingredient supplier—expanded its venture arm to support startups optimizing membrane filtration and ultrasound-assisted extraction of zeaxanthin, with pilot investments in both China and Southeast Asia. The company has signaled intentions to double its funding allocation for microalgae extraction startups through 2027, reflecting both regional market growth and technological maturation.

The United States is also seeing a flurry of activity. Heliac Bio, a biotech startup specializing in microalgae photobioreactor systems and green extraction techniques, closed a $12 million Series B round in March 2025 to scale up its solvent-free zeaxanthin extraction lines. The company’s modular systems have attracted attention from both agri-food and cosmetics industry partners seeking clean-label zeaxanthin sources.

Looking ahead, analysts anticipate increased strategic investment from established ingredient suppliers and food conglomerates, especially as regulatory approvals for microalgae-derived zeaxanthin broaden in North America and Europe. The trend is toward vertically integrated platforms—startups that combine proprietary cultivation, extraction, and downstream formulation—making them attractive acquisition targets for larger players seeking to bolster their natural carotenoid portfolios.

Overall, the outlook for 2025 and beyond suggests robust funding flows into zeaxanthin microalgae extraction technologies, with particular emphasis on energy-efficient, solvent-free, and scalable processes. As more pilot projects reach commercial viability, the sector is poised for continued growth and increased merger and acquisition activity by mid-decade.

Downstream Applications: Nutraceuticals, Food, and Pharma Opportunities

In 2025, the extraction of zeaxanthin from microalgae is receiving unprecedented attention due to surging demand in nutraceutical, food, and pharmaceutical markets. Zeaxanthin, valued for its role in eye health and antioxidant properties, is increasingly sourced from microalgae such as Dunaliella salina and Chlorella zofingiensis, which offer higher yields and more sustainable production compared to traditional marigold flower extraction. Recent advances focus on optimizing both yield and purity, as well as reducing environmental impact and operational costs.

Significant strides have been made in developing scalable and efficient extraction technologies. Supercritical CO2 extraction has emerged as a leading method due to its selectivity, lack of toxic solvent residues, and scalability. Companies like Algatech have invested in proprietary supercritical CO2 systems specifically tailored for carotenoids, enabling the production of food-grade and pharmaceutical-grade zeaxanthin. These methods are increasingly automated and include integrated downstream purification steps, such as molecular distillation and chromatographic techniques.

Another trend in 2025 is the adoption of green extraction techniques. eBionatura has reported success with enzyme-assisted extraction, which uses cellulase and pectinase enzymes to break down microalgal cell walls, improving zeaxanthin recovery while minimizing degradation. This method aligns with the growing preference for solvent-free, eco-friendly processes in the food and nutraceutical sectors.

Membrane filtration and aqueous two-phase extraction (ATPE) are also gaining ground as alternatives. Parry Nutraceuticals is piloting ATPE systems that allow for selective partitioning of zeaxanthin in water-based environments, reducing reliance on organic solvents and facilitating easier scale-up for commercial production. Such technologies are expected to become more widespread within the next few years as regulatory and consumer pressure mounts for cleaner extraction processes.

Looking forward, the outlook for zeaxanthin microalgae extraction technologies is robust. As clinical evidence supporting zeaxanthin’s health benefits continues to accumulate, manufacturers are actively expanding capacity and refining downstream processes to achieve higher purity and meet stringent food and pharmaceutical standards. Industry collaborations are anticipated to accelerate technology transfer, with microalgae producers such as Fuqing King Dnarmsa Spirulina and ingredient suppliers investing in integrated biorefinery models. These advances are set to make microalgal zeaxanthin a mainstream ingredient across nutraceuticals, functional foods, and pharmaceutical applications by the late 2020s.

Sustainability & Environmental Impact of Extraction Technologies

In 2025, the sustainability and environmental impact of extraction technologies for zeaxanthin from microalgae are increasingly central to both commercial scaling and regulatory compliance. As demand for natural zeaxanthin rises—driven by its use in eye health supplements and functional foods—producers are adopting more eco-friendly processes to align with global sustainability standards.

Traditional solvent-based extraction methods, which often rely on petroleum-derived solvents like hexane or acetone, are being phased out in favor of greener alternatives. These conventional techniques pose risks of solvent residues, generate hazardous waste, and have high energy footprints. In response, several leading microalgae producers are implementing supercritical fluid extraction (SFE), especially using supercritical CO2. This method eliminates the need for toxic organic solvents, reduces waste, and allows for solvent recycling, significantly lowering environmental impact. For example, Algatech (a subsidiary of Solabia Group) utilizes SFE for zeaxanthin and other carotenoids, highlighting its lower carbon footprint and minimal waste generation.

Another notable development is the use of enzymatic and mechanical cell disruption techniques, such as high-pressure homogenization and bead milling, which further minimize chemical inputs and water usage. Parry Nutraceuticals employs such mechanical processes in their integrated production lines, enabling high recovery rates of zeaxanthin while maintaining energy efficiency.

Closed photobioreactor cultivation systems, paired with these advanced extraction technologies, are gaining traction. Such systems reduce water consumption, prevent contamination, and enable nutrient recycling. Companies like Fuqing King Dnarmsa Spirulina emphasize the use of closed-loop processes, supporting both sustainable cultivation and downstream extraction of carotenoids, including zeaxanthin.

On the regulatory front, environmental standards for food-grade and nutraceutical ingredients are tightening in North America, Europe, and Asia-Pacific markets. Producers are thus investing in Life Cycle Assessment (LCA) studies and eco-certifications to validate their environmental claims. The European Algae Biomass Association (EABA) is actively promoting best practices for sustainable microalgae processing, including guidance on extraction technology selection and waste management.

Looking ahead, further improvements are anticipated by 2027, with ongoing research into solvent-free extraction and hybrid mechanical-enzymatic processes. As the sector evolves, sustainability will remain a key differentiator, shaping supply chain partnerships and end-user acceptance of microalgae-derived zeaxanthin.

Emerging Markets: Geographic Hotspots & Regional Demand Analysis

The global landscape for zeaxanthin microalgae extraction technologies is rapidly evolving, with significant momentum observed in certain geographic hotspots as of 2025. Key drivers include the rising demand for natural carotenoids in nutraceuticals, functional foods, and eye health supplements, as well as regional initiatives for sustainable bioproducts. Notably, Asia-Pacific, North America, and parts of Europe are emerging as focal areas for both production innovation and market consumption.

- Asia-Pacific: China continues to dominate microalgae cultivation and extraction capacities, leveraging its established infrastructure and cost-effective production ecosystems. Leading companies such as Fuqing King Dnarmsa Spirulina Co., Ltd. and Fengchen Group Co., Ltd. are expanding production lines focused on zeaxanthin-rich microalgae like Spirulina and Chlorella. The region’s technological advancements include the adoption of supercritical CO2 extraction and membrane separation, improving both yield and purity for finished zeaxanthin extracts.

- Europe: European Union regulations favoring natural colorants and sustainable food ingredients are boosting investments in algae-based zeaxanthin extraction. Companies such as Algatech LTD (Israel, with strong EU market penetration) are pioneering closed-system photobioreactors and eco-efficient downstream processing. These innovations address both scalability and environmental compliance, positioning Europe as an innovation hub for premium zeaxanthin ingredients.

- North America: The United States is witnessing increased R&D activity, particularly in California and the Pacific Northwest, where companies such as Solazyme (now Corbion) and Cyanotech Corporation are piloting next-generation extraction methods like enzymatic digestion and ultrasound-assisted extraction. These technologies enable higher selectivity and product stability, meeting the rising consumer demand for clean-label and vegan products.

Looking ahead to the next few years, regional demand is expected to surge, particularly in Southeast Asia and South America, where climatic conditions favor cost-effective algae cultivation. As regulatory acceptance of algae-derived zeaxanthin broadens, especially in India and Brazil, localized extraction facilities are anticipated to emerge. Globally, the convergence of sustainable processing technologies and health-focused applications will continue to drive both supply- and demand-side growth. Industry participants are likely to emphasize traceability, non-GMO certifications, and scalable green extraction platforms to differentiate in increasingly competitive markets.

Future Outlook: Disruptive Technologies and Strategic Roadmap for Industry Stakeholders

In 2025 and the coming years, zeaxanthin microalgae extraction technologies are poised for significant transformation, driven by advances in bioprocessing, sustainability imperatives, and strategic collaborations. The traditional reliance on organic solvent extraction is being challenged by a new wave of disruptive technologies that promise higher yields, improved purity, and lower environmental impact.

One of the most promising developments is the adoption of supercritical fluid extraction (SFE), particularly using supercritical CO2. This technology has been increasingly adopted by companies such as Algaetech International, which reports higher recovery rates and reduced solvent residues compared to conventional methods. SFE enables selective extraction of zeaxanthin, preserving its bioactivity and meeting stringent regulatory standards for nutraceutical and pharmaceutical applications.

Simultaneously, the industry is witnessing the integration of green extraction techniques, including enzymatic and ultrasound-assisted extraction. Parry Nutraceuticals, a subsidiary of EID Parry, is investing in enzymatic disruption technologies to enhance cell wall breakdown, thereby increasing zeaxanthin recovery from microalgal biomass. These approaches offer scalability and align with the increasing demand for clean-label, sustainable ingredients.

Looking ahead, continuous processing and automation are expected to further disrupt the extraction landscape. Companies like Fuqing King Dnarmsa Spirulina are exploring modular, continuous-flow extraction units that improve throughput and reduce production costs, which is vital for meeting the rising global demand for zeaxanthin in eye health supplements and functional foods.

Strategically, industry stakeholders are forging partnerships across the value chain—from microalgae cultivators to end-product formulators—to accelerate technology adoption and product development. Cyanotech Corporation has announced collaborations with downstream processors to optimize extraction protocols tailored to specific product applications, indicating a trend towards vertically integrated supply chains.

In terms of regulatory and market outlook, alignment with evolving food and pharma safety standards remains a top priority. Companies are investing in traceability and quality assurance systems, as evidenced by DIC Corporation’s initiatives in microalgae ingredient traceability and compliance.

Overall, the strategic roadmap for zeaxanthin microalgae extraction technologies includes the adoption of cleaner, more efficient extraction methods, process automation, and collaboration across the supply chain. These advances are set to enhance product quality, sustainability, and scalability, positioning the sector for robust growth as global demand for natural zeaxanthin continues to rise through 2025 and beyond.