- Mobis India Limited, in partnership with Hyundai Motor India, has launched a cutting-edge EV Battery System Assembly plant in Sriperumbudur, Tamil Nadu.

- The facility covers 8.15 acres and underscores India’s push towards sustainable mobility.

- Initial production targets 36,000 units annually, with plans to increase to 75,000 units, focusing on Nickel-Manganese-Cobalt battery packs.

- The Hyundai Creta Electric is the first vehicle to utilize the plant’s battery packs.

- The plant will generate 255 direct and indirect job opportunities, fueling eco-conscious economic growth.

- This venture emphasizes localization, reducing dependency on international components and enhancing India’s self-reliance in the EV sector.

- The plant is a significant milestone in India’s journey towards an electrified future and sustainable automotive innovation.

The buzz of industry fills the air in the heart of Tamil Nadu as a pioneering facility quietly powers up. Mobis India Limited, in close collaboration with Hyundai Motor India Limited, has opened a state-of-the-art EV Battery System Assembly plant in Sriperumbudur, paving the way for a greener tomorrow.

Spread across 8.15 sprawling acres, this ultramodern plant stands as a testament to India’s burgeoning commitment to sustainable mobility. Nestled next to Hyundai’s bustling car manufacturing hub, the facility hums with the potential of innovation. Designed to invigorate the electric vehicle (EV) sector, the plant boasts an initial production capacity of 36,000 units annually, with visionary plans to scale up to 75,000 units.

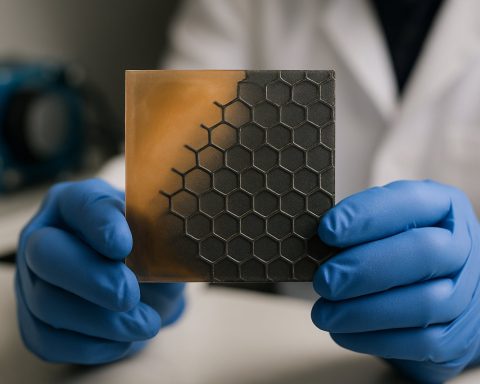

The immediate beneficiary of this enterprise is the Hyundai Creta Electric, a marquis EV that will be the first to run with battery packs assembled at this very site. Currently, the plant focuses its energy on mastering Nickel-Manganese-Cobalt battery packs, with a roadmap to incorporate Lithium-Iron-Phosphate technology, propelling it into a new era of efficiency and performance.

Against the backdrop of gleaming machines and precise engineering, the facility doesn’t just reveal a concrete structure but a new facet of India’s industrial landscape. It promises to create 255 direct and indirect job opportunities, weaving economic growth into the fabric of eco-conscious development.

Industrial leaders and government officials alike herald this plant as a landmark stride towards localization. Key components that were once sourced from far-flung locations will now be crafted on Tamil Nadu soil, a crucial step towards bolstering India’s self-reliance in the EV domain.

As we stand on the brink of an electric future, this new plant in Sriperumbudur marks a pivotal point along the journey. It symbolizes a blend of ambition and commitment, echoing a powerful narrative: India is not merely catching up with global trends but setting the pace for sustainable innovation. The horizon of India’s automotive industry dazzles with potential, charging ahead towards a cleaner, greener destiny.

Revolutionizing India’s EV Future: A Deep Dive into Mobis and Hyundai’s New Battery Plant in Tamil Nadu

Expanding Horizons in the EV Industry

Mobis India Limited, in collaboration with Hyundai Motor India, has strategically chosen Sriperumbudur for its state-of-the-art EV Battery System Assembly plant. This move not only underscores India’s commitment to green technology but also positions the nation as a formidable player in the global electric vehicle market.

How-To: Steps for Setting Up a Successful EV Battery Plant

1. Feasibility Study: Conduct a thorough analysis of the proposed location’s infrastructure, workforce availability, and logistics.

2. Technology Selection: Decide on the type of battery technology to focus on, such as Nickel-Manganese-Cobalt or Lithium-Iron-Phosphate, based on market demand and efficiency.

3. Partnerships and Collaboration: Forge alliances with automobile manufacturers for immediate demand fulfillment.

4. Sustainability Planning: Implement eco-friendly practices and materials in the manufacturing process to align with global green standards.

5. Regulatory Compliance: Ensure that all operations meet local and national environmental regulations.

Real-World Use Cases

– Hyundai Creta Electric: The first recipient of the Sriperumbudur plant’s battery packs, highlighting immediate integration into consumer vehicles.

– Localized Component Manufacturing: By reducing dependency on imported materials, Mobis can offer competitive pricing and faster production cycles, benefiting the entire EV ecosystem.

Market Forecasts & Industry Trends

The global electric vehicle market is projected to grow at a CAGR of around 21.7% through 2030, according to Allied Market Research. India’s contribution, spearheaded by companies like Hyundai and Mobis, is expected to rise significantly as infrastructure improvements continue.

Pros & Cons Overview

Pros:

– Economic Growth: 255 new jobs will propel the local economy and reduce unemployment.

– Technological Advancements: With a focus on Nickel-Manganese-Cobalt and future shifts to Lithium-Iron-Phosphate, the plant promises cutting-edge technology.

– Environmental Impact: Local manufacturing reduces carbon footprints from transport, aligning with eco-friendly goals.

Cons:

– High Initial Investment: Setting up such facilities requires substantial capital and rigorous planning.

– Technological Uncertainties: Rapid changes in battery technologies may demand continuous upgrades and investments.

Insights & Predictions

With growing government incentives and consumer interest, India’s EV adoption rate is set to spike. Facilities like this will likely see increased demand, pushing capacity beyond anticipated levels much earlier than planned.

Actionable Recommendations

– For Investors: Consider investments in ancillary industries like battery recycling or EV charging infrastructure for portfolio diversification.

– For Consumers: Keep an eye on upcoming models of Hyundai EVs that will feature locally made battery packs as these might offer better maintenance and operational support.

Quick Tips for Manufacturers

– Capacity Building: Plan for flexible manufacturing capabilities that can expand or adapt to new technologies with minimal downtime.

– Skill Development: Invest in training programs to ensure the workforce remains adept at handling evolving technologies.

Relevant Link

Learn more about India’s automotive developments by visiting Hyundai.

By building on this cutting-edge facility, India takes a bold step towards an electrified future, challenging the world’s major economies in innovation and sustainability.