- Porsche is pioneering sustainable innovation by launching a pilot project to recycle EV batteries in a closed-loop system.

- The initiative focuses on reusing metals from derelict batteries, minimizing environmental impact, and supporting a “Circular Economy.”

- Key phases involve shredding old batteries to extract valuable materials like nickel, cobalt, manganese, and lithium, which are then purified and used to create new batteries.

- Recycling efforts align with upcoming regulatory standards and aim to reduce raw material dependency amidst global market fluctuations.

- Porsche’s commitment enhances its environmental responsibility and sets a new benchmark for sustainability within the auto industry.

Beneath the sleek exteriors and roaring legacy of Porsche’s high-performance vehicles hums a quieter, revolutionary ambition—a vision for a future where high-voltage batteries find new life beyond the confines of their initial automotive purpose. In a daring new initiative, Porsche steps forward as a leader in sustainable innovation, launching a pilot project aimed at recycling their electric vehicle (EV) batteries in a closed-loop system.

Imagine a world where the metals coursing through the veins of a luxury EV once powered another, now reborn without the heavy environmental toll of mining. This is precisely the future Porsche envisions. As they maneuvre through the complex landscape of sustainability, they’ve embraced the mantra: “reduce, reuse, recycle.”

With the stunningly silent Porsche Taycan as a testament to their electric prowess, Porsche has taken bold steps into the electric arena. But it’s the hidden components—the batteries—that have captured their current focus. These are not merely batteries; they’re part of a broader narrative of our changing relationship with raw materials and the earth itself.

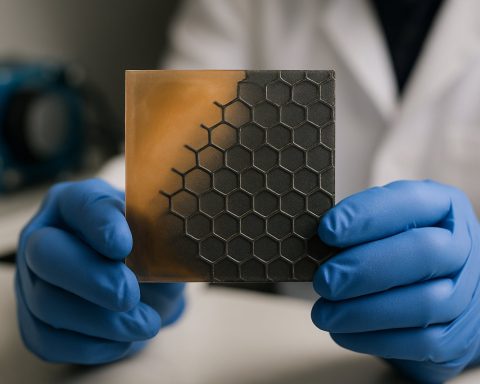

Porsche’s pilot program embarks on a transformative journey through three phases aimed at achieving a “Circular Economy.” In the first stage, derelict batteries from trial vehicles are shredded and their core components extracted as a “black mass.” This unassuming substance holds the potential goldmine of nickel, cobalt, manganese, and lithium. It’s the new-age alchemy that could forever change the manufacturing of EV batteries.

The saga continues as these elements undergo rigorous purification, matching the quality of brand-new materials. Porsche’s dedication to refining recycled components is nothing less than an orchestration of science and ambition, tuning recovered materials into a symphony comparable to their pristine counterparts.

In the final movement of this process, Porsche’s recovered components are reincarnated into virginal batteries, ready to power the next generation of electric marvels. This approach doesn’t just meet regulatory expectations—like the anticipated 2031 EU battery requirements—but it challenges the auto industry to rise above existing paradigms.

As the world’s geopolitical landscapes shift and the price of raw materials wax and wane, Porsche’s initiative sets a new benchmark in environmental responsibility. By placing circularity at its core, the company underscores a deep commitment to reducing its ecological footprint and expanding the lifespan of our planet’s finite resources.

This project heralds a new chapter for Porsche and its partners in sustainability, where innovation drives not just the speedometer, but the pulse of our planet. As the rubber meets the road, Porsche isn’t just moving forward—it’s redefining the journey altogether.

Revolutionizing the Road: Porsche’s Bold Step Towards Battery Reincarnation

The Porsche Revolution in Electric Vehicle Battery Recycling

Porsche, renowned for its luxurious and high-performance automobiles, is steering towards a path of sustainability, emphasizing the recycling and efficient use of electric vehicle (EV) batteries. Let’s dive deeper into this innovative venture, unravel how it could reshape the auto industry, and explore additional insights surrounding this groundbreaking project.

How Porsche is Leading the EV Battery Recycling Movement

1. Circular Economy Commitment: Porsche’s objective is to establish a closed-loop system where used EV batteries are completely recycled. This system aims to maximize the use of existing materials, thus reducing the need for new resource extraction.

2. Black Mass Extraction Process: The process starts with dismantling and shredding old batteries, transforming them into a ‘black mass’. This substance holds valuable metals like nickel, cobalt, manganese, and lithium, which are crucial components for manufacturing new batteries.

3. Purification and Refining: Porsche ensures the extracted materials match the quality of newly sourced ones through rigorous purification processes. This not only maintains the performance standards Porsche is known for but also fosters sustainable manufacturing practices.

4. Regulatory Compliance and Leadership: Porsche’s strategy is not just about compliance with the upcoming 2031 EU battery regulations; it’s about setting new industry standards in sustainability.

Real-World Use Cases and Industry Trends

– Sustainability in Luxury Brands: Porsche’s efforts highlight a growing trend among luxury brands to incorporate sustainable practices. This not only appeals to environmentally conscious consumers but also sets a standard for other automakers to follow.

– Market Shifts: As raw materials become more expensive and geopolitically sensitive, Porsche’s model presents a viable alternative that reduces dependency on new mining endeavors.

Environmental Impact and Long-Term Benefits

– Reduced Environmental Footprint: By recycling and reusing battery components, Porsche minimizes the ecological impact associated with mining and new material production.

– Extension of Material Lifespan: Enhancing the lifecycle of raw materials conserves natural resources and showcases Porsche’s commitment to environmental stewardship.

Industry Comparisons and Controversies

– Competitive Landscape: Many automakers are exploring battery recycling. However, Porsche’s initiative stands out for its comprehensive closed-loop system, from extraction to manufacturing.

– Challenges and Limitations: The complexity of recycling operations, cost implications, and the need for technological advancements are some challenges Porsche must overcome.

Actionable Recommendations and Quick Tips

– Consumer Awareness: Car buyers can support sustainable practices by choosing brands with transparent and effective recycling programs.

– Industry Collaborations: Automakers can collaborate with tech companies to enhance recycling technologies and processes.

Future Insights and Predictions

– Technological Advancements: Expect advancements in battery recycling technology to improve efficiency and reduce costs.

– Broader Industry Adoption: As Porsche demonstrates success, more manufacturers may adopt similar closed-loop systems, accelerating the transition to sustainability.

Porsche’s endeavor to revolutionize EV battery recycling is a testament to their forward-thinking and eco-conscious strategy. For more on how luxury meets sustainability, visit Porsche.