- Porsche is revolutionizing EV battery recycling, potentially setting a new industry standard.

- The process involves transforming batteries into “black mass,” extracting key metals like lithium, nickel, cobalt, and manganese for reuse.

- Porsche aims to meet Europe’s regulatory goals, recovering 80% of lithium by 2031.

- The initiative addresses raw material volatility and aims to establish a sustainable, closed-loop system.

- Porsche has processed 65 tons of material, showing promise despite the pilot project status.

- Combining sustainability with luxury, Porsche’s approach reduces dependency on uncertain supplies and foresees market needs.

- The venture highlights Porsche’s commitment to innovation, engineering excellence, and ecological responsibility.

A new dawn is breaking over the automotive horizon, and at its heart lies a remarkable ambition: transforming the way we handle electric vehicle (EV) batteries. Among the vanguards of this technological renaissance is Porsche, whose recent venture into battery recycling could well become a blueprint for the entire industry.

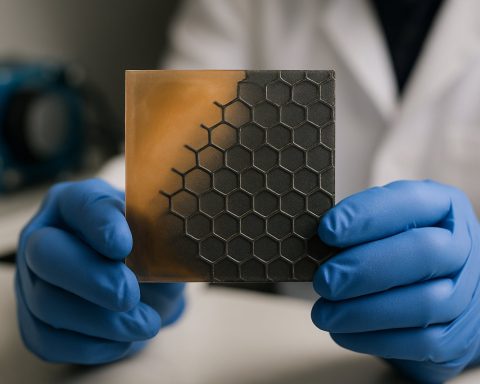

Imagine a robust, agile machine devouring discarded high-voltage batteries at one of Porsche’s cutting-edge facilities. These once-powerful cells, reduced to a granular substance known as “black mass,” hold a treasure trove of coveted metals: lithium, nickel, cobalt, manganese—elements vital for crafting the next generation of electric cars. This meticulous process is not just a technological endeavor but a necessary evolution, as the global markets for raw materials remain volatile and geopolitically fraught.

With striking precision, Porsche is extracting the promise of new beginnings from these spent powerhouses. The black mass is meticulously refined, separating out individual raw components ready to spark life into new batteries destined for the iconic Porsche silhouette. The ambition? To recycle and innovate simultaneously, aligning with Europe’s bold regulatory landscapes which aim for an 80% recovery rate of lithium by 2031. As of now, only 5% of lithium-ion batteries escape the fate of neglect, demonstrating Porsche’s potential to lead a revolution littered with financial and environmental incentives.

Thus far, Porsche has yielded 65 tons of this precious material, and while it remains in the pilot phase, the implications are vast. Beyond compliance, this venture offers a glimpse into a future where the automotive industry not only responds to market demands but anticipates them, creating a closed-loop system that mirrors nature’s efficiency.

In the bustling race toward sustainable luxury, Porsche’s pursuit could very well pave the way for others. By integrating these reformed resources, they are not just reducing dependency on unstable supplies but are proactively sculpting the fabric of modern manufacturing.

This initiative underscores a pivotal truth: the road to a sustainable future is paved not just with innovation, but with an unyielding commitment to engineering excellence and ecological responsibility. As the auto industry steers toward this new epoch, Porsche’s ambitious quest to master the cycle of battery life is a testament to where passion meets responsibility. Where ingenuity intertwines with nature.

How Porsche’s Battery Recycling Innovation Could Transform the Automotive Industry

Introduction

Porsche’s initiative in electric vehicle (EV) battery recycling is set to redefine industry standards, aligning with sustainability and resource efficiency. As the auto industry increasingly prioritizes environmental responsibility, Porsche’s innovative approach to recycling could lead to a new era of closed-loop manufacturing, reducing reliance on resource-intensive mining.

The Process of Battery Recycling

At its core, Porsche’s method involves dismantling used high-voltage batteries to extract “black mass”—a substance rich in vital metals like lithium, nickel, cobalt, and manganese. This resource recovery can significantly offset the demand for newly mined materials, addressing both economic and ecological concerns.

The Importance of Black Mass Recovery

– Environmental Impact: By separating and utilizing black mass, Porsche reduces environmental strain associated with traditional mining, promoting sustainability.

– Economic Efficiency: The process not only saves costs but also allows Porsche to maintain a stable supply of critical materials, crucial given the volatile nature of global raw material markets.

– Strategic Alignment: Porsche’s commitment aligns with the European Union’s regulatory goal of an 80% lithium recovery rate by 2031.

Industry Trends and Market Forecasts

As regulatory pressures mount and consumer demand for sustainable practices increases, other manufacturers may follow Porsche’s lead, adopting similar recycling methods. The transition towards closed-loop systems could define future industry standards, making the automotive sector less dependent on geopolitically sensitive resources.

The Pros and Cons of Porsche’s Approach

Pros:

– Enhanced Sustainability: Reducing reliance on virgin material extraction.

– Economic Resilience: Mitigating risks linked with raw material supply chains.

– Innovation Leadership: Positioning Porsche as a pioneer in automotive sustainability.

Cons:

– Initial Costs: High upfront investment required for scaling up processes.

– Complex Technology: The need for continual technological advancements to maintain efficiency.

Real-World Implications

This initiative by Porsche not only positions the brand favorably among eco-conscious consumers but also sets a precedent for other automotive companies aiming for sustainable luxury. Furthermore, the potential market stability in raw materials could offer broader economic benefits, influencing global supply chains.

Future Perspectives and Actions

To capitalize on these opportunities, automotive manufacturers should:

– Invest in Research: Amplify R&D efforts to improve recycling technology.

– Collaborate: Partner with governments and industries to enhance recycling infrastructure.

– Educate Consumers: Advocate for the benefits of recycled materials in EVs.

Conclusion

Porsche’s pioneering battery recycling is more than an industry innovation—it’s a movement toward a sustainable automotive future. As Porsche continues to refine its recycling methods, it stands as a beacon for other manufacturers. This momentum underscores the critical intersection between technology and sustainability, guiding the industry toward a cleaner, more efficient future.

Explore more about Porsche’s sustainability initiatives at Porsche.