- A steep 64.9% tariff on Chinese battery cells threatens to elevate U.S. EV production costs significantly.

- Former President Trump’s policies, including tariff impositions and revoking EV incentives, push a return to traditional fuel vehicles.

- China’s dominance in battery supply means increased costs could drive up EV prices, deterring consumers.

- Tesla’s drop in deliveries highlights potential instability in the EV market; JP Morgan notes possible brand damage.

- This policy shift could bolster U.S. domestic battery production, though it requires substantial investment and time.

- The situation presents a strategic challenge for the U.S. to maintain its path towards sustainable energy amidst new barriers.

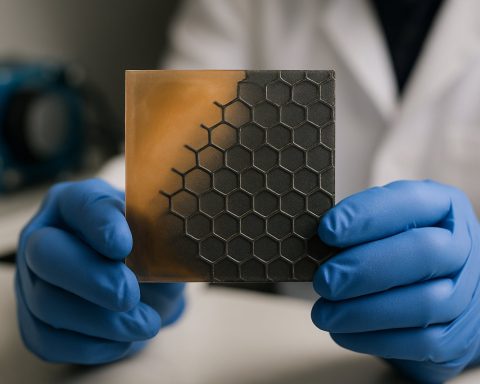

The sparks of innovation that once lit up the U.S. electric vehicle (EV) industry are facing a chilling wind, as aggressive tariffs threaten to upend the momentum that had consumers leaning towards a cleaner, electric future. At the heart of this seismic shift is a stark 64.9% tariff on Chinese battery cells, a critical component in EV production that could drastically elevate costs.

American consumers, who have been slowly embracing the electrification of their driveways, might find themselves once again courting gas-guzzling models. Former President Donald Trump’s decisive policies, which include not only tariffs but also the revocation of key EV mandates and tax credits, signal a distinct pivot back towards traditional energy sources and away from the pro-EV stance of previous administrations.

The timing couldn’t be more precarious. While the automotive world was bracing for a rapid shift towards electric models, these tariffs cast a long shadow over the industry’s plans. China’s dominant role as a supplier of battery cells means any increased costs there ripple through to retail prices, making EVs a heftier financial commitment for buyers. The average battery pack, which once cost around $10,000 to $12,000, might see price surges that could render EV options less appealing to the average consumer, who is sensitive to price, charging logistics, and significant infrastructure changes.

The policy change rattled not just environmentalists but also Wall Street, where Tesla’s unexpected drop in deliveries underscored the industry’s fragility. Once heralded as a beacon for EV success, Tesla’s decrease to 336,681 units — below expectations and its lowest in years — signals broader tremors in the EV market. As JP Morgan cools on Tesla, considering ‘unprecedented brand damage,’ the fear is not just about a single company but a paradigm shift across the sector.

Interestingly, Trump’s move does present a silver lining: the incentive for the U.S. to localize its battery cell production. This offers a dual benefit – reducing reliance on foreign imports while potentially cultivating a burgeoning new industry within U.S. borders. However, this is no small feat, requiring significant time and investment to catch up with the technological prowess and scale of leading producers like China.

If anything, these developments paint a complex picture of the future. The once inevitable transition to electric may stall unless innovation can outpace the new hurdles. The U.S. now faces a challenge: can it navigate these turbulent times and retain its path towards sustainable energy? As the landscape shifts, so too must the strategy, invoking a call to action for lawmakers, companies, and consumers alike to reimagine their roles in an electrified future. The road ahead demands resilience and adaptability — perhaps the true keystones of progression.

The Uncertain Future of the U.S. Electric Vehicle Market: Challenges and Opportunities

The sparks of innovation that once electrified the U.S. electric vehicle (EV) industry are now confronted by significant challenges, as aggressive tariffs and policy shifts threaten to disrupt the momentum toward a cleaner, greener future. The imposition of a 64.9% tariff on Chinese battery cells is a critical development that could significantly impact the industry. However, this situation also offers unique opportunities for growth and innovation within the U.S. market.

How Tariffs Influence the EV Market

The substantial 64.9% tariff on Chinese battery cells is poised to elevate costs across the board for electric vehicles. Since these battery cells are fundamental to EV production, any price increase affects the overall retail pricing. This could make electric vehicles a less appealing option for price-conscious consumers, thereby potentially slowing down the adoption of EVs in favor of traditional, gas-powered vehicles.

Key Challenges Facing the U.S. EV Industry

1. Increased Production Costs: Battery packs, which once cost around $10,000 to $12,000, are susceptible to price hikes due to the tariffs, posing a risk to the affordability of EVs.

2. Potential Slowdown in EV Adoption: With the added financial burden, American consumers might be less inclined to purchase electric cars. This challenges automakers’ plans and their investment in EV infrastructure.

3. Supply Chain Disruptions: Dependence on Chinese battery cells underscores a vulnerability that needs addressing if the U.S. is to stabilize its EV production and sustain growth.

Opportunities for Domestic Innovation and Growth

On the flip side, the current scenario encourages the U.S. to strengthen its local production capabilities:

1. Localization of Battery Production: There is an opportunity to build domestic battery manufacturing, which could reduce reliance on imports and foster job creation in the U.S.

2. Technological Advancements: Innovating in battery technology could lead to the development of more efficient, cost-effective solutions, boosting the appeal of EVs in the market.

3. Government Incentives and Investments: Policymakers could play a crucial role by providing subsidies and tax incentives to support local manufacturing, thus attracting more investment into the sector.

Pressing Industry Questions

– Will the U.S. EV Industry Adapt? The ability of automakers to innovate and reduce costs is key to addressing these tariff-induced challenges.

– Can Local Production Meet Technological Demands? Meeting the technological standards set by international producers like China will require significant investment in R&D.

Real-World Use Cases and Predictions

Despite these challenges, the future is not all bleak:

– Collaboration Opportunities: Collaborating with American tech firms could accelerate advancements in battery efficiency and production.

– Forecasted Industry Trends: There’s potential for a robust domestic supply chain to emerge, offering both economic and environmental benefits as it reduces the carbon footprint associated with international shipping.

Recommendations and Quick Tips for Consumers

– Stay Informed: Consumers should keep abreast of changes in EV pricing and availability, considering both new and second-hand vehicles as viable options.

– Consider Long-Term Benefits: While upfront costs might increase, the long-term savings on fuel and maintenance, coupled with environmental benefits, should also weigh into decision-making.

– Leverage Available Incentives: Watch for government incentives that could offset increased costs, such as federal tax credits or state-specific rebates.

As the U.S. navigates these turbulent times, it’s crucial for stakeholders to remain resilient and adaptable. Policymakers, companies, and consumers must rethink their strategies to answer the call for sustainable energy solutions in an ever-evolving landscape. The path forward may bring challenges, but it also holds the promise of a more sustainable future.