- Altilium, a UK-based leader in sustainability, is paving the way for recycling EV batteries with their innovative EcoCathode materials.

- At the UK Battery Industrialisation Centre, Altilium has successfully replicated the performance of traditional battery cells using recycled materials, demonstrating a viable alternative to newly mined metals.

- The process recovers 95% of essential metals, including lithium, from used EV batteries, exemplifying circular economy principles.

- Performance metrics of recycled cathodes show less than 1% variance compared to conventional materials, ensuring industrial acceptance.

- This breakthrough reduces reliance on imported battery materials and promotes a sustainable manufacturing ecosystem in the UK.

- Altilium’s efforts signify a shift towards battery circularity and reduced CO2-heavy mining practices.

- The partnership between Altilium and UKBIC heralds a new dawn for sustainable innovation, with reclaimed batteries poised to redefine future generations.

Electric vehicles (EVs) symbolize the charge towards a cleaner future, but as roads fill with these silent warriors, a pressing dilemma looms—what to do with the deluge of dead batteries? A UK-based frontrunner in cutting-edge sustainability, Altilium, may have just illuminated a path forward, showcasing a trailblazing shift in the lifecycle of battery materials.

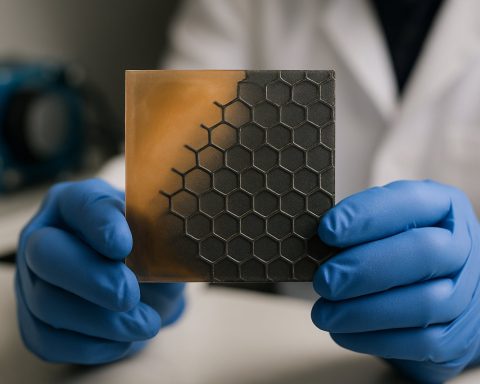

In the heart of Coventry at the state-of-the-art UK Battery Industrialisation Centre (UKBIC), a quiet revolution is taking place. Here, Altilium’s pioneering team has challenged the status quo by replicating the performance and manufacturability of conventional battery cells using their innovative EcoCathode materials. This is not just a technical victory; it embodies a paradigm shift as recycled cathodes are revealed to be a genuine alternative to freshly mined metals.

Imagine intricate, silvery webs of pouch cells coming to life in a high-tech crucible of invention. These aren’t ordinary cells. They are crafted from Altilium’s recycled EcoCathode NMC 811-2036 CAM, a miracle concoction born from the ashes of yesterday’s EVs. What stands out is the unbelievable transformation of waste into a resource—recovering an impressive 95% of essential metals, including the much-coveted lithium.

Altilium’s results are a profound empowerment of circular economy principles. They revealed a negligible variance—less than 1%—in performance metrics compared to traditional materials, a testament to their rigorous research and development. The manufacturability mirrored that of usual industry practices, obliterating any industrial doubts with the triumph of sustainable technology over ecological adversity.

Beyond the realm of science and numbers, Altilium’s triumph symbolizes the dawn of a potential revolution, liberating the UK from its dependency on imported battery materials. This innovation fuels hope, not just for a single company, but for the nation’s industrial future—a less carbon-heavy, more sustainable manufacturing ecosystem.

Dr. Christian Marston, Altilium’s dynamic co-founder, eloquently described these milestones as pioneering steps in achieving battery circularity. It’s a vision where the lifespan of resources is extended and the invasion of CO2-heavy mining practices is curtailed—a vision not too far from becoming reality.

With every test, Altilium inches closer to fortifying a robust recycled battery market, a market poised to redefine the landscape for future generations. As this unprecedented era begins to unfold, Altilium and UKBIC’s partnership stands as a beacon of hope and innovation, a guidebook on reintegrating what once seemed like the end of the line.

As the narrative threads of technology and sustainability weave tighter, the UK finds itself at the heart of a pioneering movement. This audacious journey may one day become a case study of transformative sustainability, shaping not just the future of EVs, but the very essence of how we interact with our technological leftovers.

Stay tuned to witness the potential of reclaimed batteries, and perhaps consider a future where ‘waste’ becomes a cornerstone of prosperity rather than an end-note of consumption.

How Altilium’s Recycled Battery Revolution Could Change the Sustainability Landscape Forever

Unveiling New Horizons in Battery Recycling

The advent of electric vehicles (EVs) promised a greener future, yet the challenge of handling the deluge of dead batteries remains. However, Altilium, a leader in sustainable innovation based in the UK, is pioneering a transformative approach to tackle this issue. Through their groundbreaking work at the UK Battery Industrialisation Centre (UKBIC) in Coventry, Altilium is redefining the lifecycle of battery materials with their EcoCathode technology.

Key Insights into the EcoCathode Technology

– EcoCathode NMC 811-2036 CAM: This material is engineered from recycled components, highlighting Altilium’s commitment to sustainable practices. It achieves an impressive recovery rate of up to 95% for essential metals such as lithium, nickel, and cobalt.

– Performance Metrics: The techno-environmental breakthrough boasts a negligible variance—less than 1%—in performance compared to conventional battery materials, showcasing the refined research and development involved.

– Manufacturability: The production process of these recycled materials mirrors traditional industry practices, which means that adopting EcoCathode technology doesn’t necessitate a change in existing battery manufacturing infrastructure.

Real-World Application and Market Trends

Altilium’s innovation is not just a theoretical success but one with real-world implications. The UK’s potential liberation from dependency on imported battery materials positions it as a leader in the growing market for recycled batteries. This transformation stands as a testament to the feasibility and scalability of sustainable practices in manufacturing. According to industry forecasts, the battery recycling market is poised to grow substantially, driven by the increasing demand for EVs and the push for environmentally responsible solutions.

Challenges and Limitations

Despite the promising advancements, several challenges remain:

– Scalability: Expanding the process to a global scale will require significant investment in infrastructure and technology.

– Regulatory Hurdles: Navigating international regulations that govern the recycling of battery materials can pose challenges.

– Market Acceptance: Gaining widespread acceptance among manufacturers to transition from traditional to recycled materials will need strategic planning and advocacy.

Actionable Strategies for Eco-Conscious Companies

1. Invest in Sustainable Technologies: Companies should explore partnerships or investments in pioneering technologies like EcoCathode to stay ahead in the sustainability race.

2. Support Regulatory Changes: Advocate for regulations that favor sustainable practices and reduce barriers to recycling technologies.

3. Educate the Consumer Base: Build awareness around the benefits of recycled battery materials to encourage consumer support and market demand for sustainable products.

4. Optimize Supply Chains: Leverage recycled materials to reduce dependency on mined resources, enhancing supply chain stability and reducing ecological footprints.

The Future of Recycled Batteries

As sustainability becomes a key component of industrial processes, innovations like those pioneered by Altilium are crucial. The potential for reclaimed batteries to become a cornerstone of prosperity underscores the shift towards a circular economy.

For more insights on sustainable practices and technological innovations, visit Altilium.

By embracing these next-generation solutions, industries can work towards a less carbon-intensive future, bolstering both economic and environmental resilience for generations to come. With strategic implementation and continued innovation, the vision of battery circularity is not only possible but inevitable.