- Mustang Advanced Engineering (MAE) and Rivian Automotive have formed a pioneering partnership to advance electric vehicle (EV) technology in Irvine, California.

- The project features custom-designed testing systems, including six MAE-AWD-500-AC/EC dynamometers, tailored for Rivian’s electric SUVs, trucks, and Electric Delivery Vans (EDVs).

- One dynamometer is housed in an environmental chamber, enabling simulation of extreme cold conditions for all-weather testing and reliability assurance.

- The dynamometers are engineered to handle high-torque electric drivetrains, with 7,000 pounds of inertia, ensuring precise performance testing.

- This collaboration underscores MAE’s innovation in bespoke solutions, and highlights Rivian’s commitment to quality and sustainable electric adventure vehicles.

- The partnership exemplifies the importance of meticulous testing and custom solutions in the evolving field of automotive engineering.

Deep within the innovative heart of Irvine, California, a partnership has taken shape, pushing the boundaries of electric vehicle (EV) technology. Mustang Advanced Engineering (MAE), a true pioneer in EV testing, has unveiled a state-of-the-art installation specifically designed for Rivian Automotive, setting new standards in the industry.

This ambitious venture, nearly two years in the making, revolves around custom-designed testing systems that cater to the particular needs of Rivian’s robust lineup of electric SUVs, trucks, and Electric Delivery Vans (EDVs). At the core of this cutting-edge facility are six intricately engineered chassis dynamometers, all emanating from MAE’s renowned MAE-AWD-500-AC/EC model. These sophisticated machines are not mere instruments—they embody precision, adaptability, and sheer engineering prowess.

The three dynamometers tailored for Rivian’s SUVs and trucks, coupled with two dedicated to the EDVs, ensure each vehicle type is rigorously tested for superior performance and reliability. With one installation housed within an environmental chamber, these systems are capable of simulating extreme cold environments, demanding vehicles to showcase their mettle against nature’s harshest challenges. This feature is particularly crucial, as it allows Rivian to refine their vehicles for all-weather performance, guaranteeing that their adventures go uninterrupted.

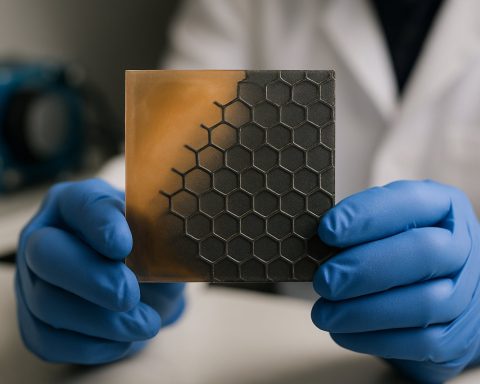

MAE’s dedication to innovation is evident in the customized nature of these testing systems. Each dynamometer is meticulously engineered to align with Rivian’s exact product specifications. Boasting a formidable 7,000 pounds of inertia, the machines handle high-torque electric drivetrains with ease, providing the steadfast loading capabilities critical for electric motors that excel at low RPMs.

Michael Caldwell, a key figure at MAE, highlights the company’s storied track record in creating test stands that deliver unparalleled torque capacity needed for electric drivetrains. The collaboration with Rivian is yet another testament to MAE’s ability to innovate and provide bespoke solutions that address the complex demands of modern electric vehicles.

For Rivian, this partnership represents more than just a technological upgrade; it’s a commitment to quality and innovation. As they pave the way for the future of electric adventure, their investment in advanced testing is a pledge to consumers that every vehicle is engineered not just to meet, but to exceed, expectations.

In the ever-evolving landscape of automotive engineering, this powerful alliance serves as a vivid reminder: in the relentless pursuit of progress, meticulous testing and custom solutions form the bedrock of sustainable innovation.

Revolutionizing EV Testing: Rivian’s Innovative Partnership with Mustang Advanced Engineering

Introduction

Nestled in the innovative hub of Irvine, California, Rivian Automotive and Mustang Advanced Engineering (MAE) have embarked on a groundbreaking journey to redefine electric vehicle (EV) testing. Through a state-of-the-art facility and cutting-edge equipment, these industry leaders are setting new standards in ensuring the reliability and performance of EVs under a variety of conditions. This article delves into the specifics of this partnership, offering an in-depth look at the technology and future implications for the EV market.

Inside the Testing Facility

The collaboration centers around customized chassis dynamometers, particularly the MAE-AWD-500-AC/EC model, optimized for Rivian’s electric SUVs, trucks, and Electric Delivery Vans (EDVs). These dynamometers are capable of simulating rigorous road conditions, including extreme cold, thanks to an environmental chamber within the facility. This enables comprehensive testing to ensure Rivian vehicles perform optimally in various weather conditions.

How-To Steps for EV Stress Testing

1. Setup and Calibration: Dynamometers must be precisely calibrated to match the specifications of the vehicle model being tested.

2. Simulate Environmental Conditions: Use the environmental chamber to recreate extreme weather conditions, such as severe cold, to test vehicle resilience.

3. Performance Metrics Monitoring: Closely track performance metrics such as torque, efficiency, and endurance during testing.

4. Data Analysis: Analyze the collected data for insights into performance improvements or necessary adjustments.

Real-World Use Cases

– Consumer Assurance: Rigorous testing ensures reliability and increases consumer confidence, pivotal for market adoption of new models.

– R&D Optimization: Feedback from tests allows Rivian to enhance R&D processes, leading to better design and efficiency improvements.

Insights & Predictions

– Market Growth: As demand for all-weather-capable EVs increases, such advanced testing facilities will become an industry norm. Expect other manufacturers to follow suit.

– Environmental Impact: Focus on sustainable innovation should further drive Rivian’s commitment to environmentally friendly manufacturing processes, reducing overall carbon footprints.

Controversies & Limitations

– Cost Implications: High setup and operational costs of advanced testing facilities could translate to increased vehicle pricing, affecting affordability.

– Technological Dependence: Over-reliance on simulators might overshadow real-world testing, which is also crucial for comprehensive data collection.

Actionable Recommendations

– Invest in EV Education: Consumers should educate themselves on the benefits of EV testing in extreme conditions for informed decision-making.

– Consider Total Ownership Costs: When purchasing an EV, look beyond upfront costs and consider potential savings from increased reliability and efficiency.

Conclusion

Rivian and MAE’s partnership is a testament to the critical role of meticulous testing and engineering innovation in driving the EV industry forward. As the sector continues to evolve, such collaborations highlight the importance of technological advancement in achieving sustainable mobility. For consumers and industry players alike, this is a powerful reminder of the continuous need for innovation and investment in cutting-edge solutions.

For more information on cutting-edge automotive solutions, visit Rivian and Mustang Advanced Engineering.